Refrigerator doors – an open and shut case?

18th January 2017UK: A leading commercial refrigeration manufacturer has claimed that retail display cabinets with glass doors will struggle to maintain temperature In busy stores, with frequent door openings.

In the ongoing doors/no-doors debate, Suffolk-based Adande Refrigeration has carried out tests to chart the effects of increasing door openings and durations.

The industry standard for the testing of refrigerated retail display cabinets, BS EN ISO 23953, states that tests on cabinets with glass doors should be conducted with 10 door openings per hour with an opening/closing cycle of 15 seconds.

Adande argues that whilst door openings every six minutes may be representative of a low volume food retailing store, this frequency is not typical of the number of door openings in a busy supermarket or convenience store.

“There is little documentary evidence on the frequency of in-store door openings, but Orlandi et al (2013) claimed that the figure can reach 60 per hour in supermarkets and in 2011 EPEE and Eurovent stated that some food retailers have registered up to 250 door openings per hour,” the company says.

It further argues that in busy stores, with frequent door openings, cold air spillage is exacerbated, increasing warm air infiltration and the potential for raised cabinet temperatures.

“In short, the suitability of multi deck display cabinets with glass doors, for high traffic stores, is open to debate,” it states.

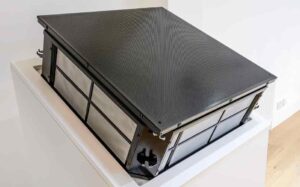

In tests carried out at its test facility in Lowestoft, Adande says it compared the operating temperature of a commercially available multi-deck refrigerated cabinet, with factory-fitted glass doors, against a comparable open front model, from the same manufacturer, modified with the Adande Aircell air flow management system. The trials were carried out under BS EN ISO 23953 conditions. Both cabinets were tested at an operating temperature of -1 to +4°C at climate class 25°C/60% RH (3M0).

After stable state running for 24 hours, the temperatures of tylose test packs at corresponding positions in each cabinet were measured at 30 second intervals over a two day period. To simulate a store environment, for a 12-hour period an automatic machine opened the glass doors 10 times per hour (every six minutes) with an opening/closing cycle of 15 seconds. The cabinet then operated for 12 hours without door openings. Temperatures recorded in the cabinet with glass doors had a range of 5°C. The Aircell cabinet is said to have maintained a much tighter temperature band of just 3.5°C, a 30% improvement.

Following further stable state running periods of 24 hours, similar tests were conducted, over three days, with a door opening frequency of 20 openings per hour for 12 hours followed by no door openings for 12 hours. During this regime, the temperature bandwidth was reported to be broader and the operating temperatures had increased.

Subsequent tests were conducted over three days with 30 openings per hour for 12 hours followed by no door openings for 12 hours. In the 30 openings per hour tests, the glass door cabinet demonstrated an even broader bandwidth and failed to recover to the operating temperature of -1 to +4°C, even after twelve hours with the doors closed.

“Understandably, many OEMs have engineered glass door cabinets to meet the BS EN ISO 23953 specification of 10 door openings per hour,” commented Adande’s managing director, Ian Wood.

“However, the evaporators specified are not capable of dealing with the higher infiltration loads associated with more frequent door openings. This results in iced evaporators and a loss of temperature control or more frequent and harsher defrost cycles with increased energy consumption. Our tests clearly demonstrate that glass doors cabinets, designed for 10 openings per hour, experience significant loss of temperature control at an opening frequency of 30 openings per hour or more.”

Adande has previously commissioned independent tests to compare the temperature performance of a conventional open front multi-deck cabinet against an identical cabinet, incorporating Aircell. Both cabinets were tested to BS EN ISO 23953 with an operating temperature of -1 to +7°C at climate class 25° C/60% RH (3M2). Over a 24-hour test period, the display cabinet modified with the Aircell system exhibited a temperature fluctuation of just 3.1°C, whilst the conventional case had an 8°C variation.