Bakery rises to 1234ze/CO2 challenge

8th May 2015

GERMANY: A refrigeration system using the low GWP HFO R1234ze in a cascade system with CO2 has been successfully applied for the first time at a bakery in Germany.

Mindful of the F-gas regulations and the HFC phase-down in Europe, Bäckerei Maurer of Winnenden, near Stuttgart, turned to this untried option when looking to provide refrigeration for its latest factory production area.

The result is what is claimed to be the first industrial installation that combines Honeywell’s Solstice ze brand R1234ze in a cacade system with CO2.

The Maurer Bakery is a family bakery and retail business preparing bread and other products to be sold in the company’s network of 42 bakery-cafe outlets in Germany. In all, Maurer employs 400 people, 70 of whom work in the company’s two production facilities.

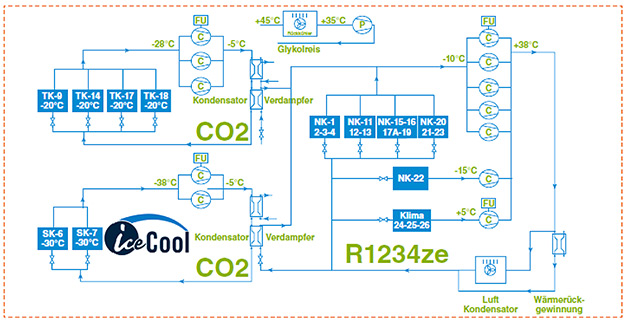

The newest factory, which extended the production surface from 2,500m² to a total of 6,000m², includes a very large preparation area, 25 cold rooms and four freezer rooms, all cooled via the cascade system, which has been designed for a life-cycle of at least 20 years.

The company took advice from its refrigeration partner, IceCool, a specialist in bakery, catering and food refrigeration. IceCool worked in collaboration with Dutch system-builder ECR Nederland and refrigerant supplier Climalife Holland to come up with the low GWP solution.

Maurer and IceCool spent six months working through the challenge of designing a cascade system that could operate efficiently and accommodate the different pressure profiles of the refrigerants, collaborating closely with ECR.

ECR-Nederland BV has a strong reputation for customised solutions, notably by applying very powerful 3D design modelling wrapped inside a full project package, compliant with PED and other regulations, and this approach was harnessed to ensure that Maurer was able to evaluate system performance and approve the overall design.

The R1234ze option was introduced to ECR by Climalife Holland, the Dutch branch of the European refrigerants distribution business. Climalife had previously participated in a number of field trials involvingHoneywell’s Solstice ze and highlighted the innovation as a future-proofed, lowest possible GWP solution. One major benefit is that 1234ze, with its GWP of <1, is not included in the quota allocations that will restrict placing HFCs in the market after 2015.

The system design was optimised to the lower pressure of Solstice ze versus the traditional refrigerant R134a. As Solstice ze is mildly flammable, IceCool checked with a notified body about ATEX compliance, who assessed that given the very low risk of Solstice ze in that system design, ATEX extra measures were not needed.

This installation also qualified for subsidies from BAFA, the German government’s Federal Office for Economic Affairs and Export Control.

Maurer commissioned the chiller/freezer system in November 2013 following extensive evaluation of Solstice ze undertaken by Climalife and ECR as part of the IceCool design.

The result is a system that combines Solstice ze for both direct expansion in medium temperature in a cascade with CO2 for low temperature.

In this system, 300kg of Solstice ze is used for direct expansion on the high side down to evaporating temperatures of -10ºC and -15ºC, feeding the cold rooms as well as the food prep areas. CO2 is used on the low side for the freezer rooms and the blast freezing process needed for some special dough products. Twelve Bitzer compressors in total are used on the system, along with electronic expansions valves on both the MT and LT operations.

“Using our long experience of working with HFCs, ammonia R290 and CO2, we have tested Solstice ze and confirmed that it has a better CoP,” said ECR-Nederland’s Udo J van der Meer. “When taking account of the total cost of ownership and failure/safety issues, we believe that Solstice ze is a perfect solution for installations such as this.”

ECR-Nederland revealed that it was currently considering Solstice ze as an option for supermarket high side refrigeration combined with CO2 on the low side.

“We had to go through a learning curve to optimise the entire installation performance, as Solstice ze and CO2 are not the easiest combination due to their very different capacities and speeds to reach steady stage,” admitted IceCool’s Peter Wehrens. “But now we are satisfied and positive that a cascade system combining Solstice ze with CO2 is a sound, reliable and efficient choice when the design and safety conditions are properly handled.”