Low GWP gases – the pros and cons

27th October 2013It is now certain that HFC refrigerants across the world are going to be subject to phase-downs and possible usage restrictions but what are the alternatives? This article takes an unbiased look at their benefits and drawbacks.

It is inevitable that HFC refrigerants will be subject to phase-downs and possible usage restrictions in most parts of the world in coming years. Europe is currently negotiating the phase-out timetable for these gases and the rest of the world is likely to bring in a similar, if less severe, timetable as part of the Montreal Protocol within the short to medium term.

It is inevitable that HFC refrigerants will be subject to phase-downs and possible usage restrictions in most parts of the world in coming years. Europe is currently negotiating the phase-out timetable for these gases and the rest of the world is likely to bring in a similar, if less severe, timetable as part of the Montreal Protocol within the short to medium term.

While the specifics are not yet known it is inevitable that HFCs, particular those with a high GWP, will cease to be the main option and some will disappear altogether.

But what are the alternatives? HFOs, “natural refrigerants”, low GWP mixed blends? It is sometimes difficult to get at the truth from the conflicting claims and vested interests of the chemical manufacturers and “green” groups.

Fortunately, a new report from UNEP’s Technology and Economic Assessment Panel (TEAP) provides an unbiased insight into the pros and cons of the most likely replacements. While ostensibly a report on alternatives to ozone depleting HCFCs, in reality it considers all the commercially available or potential alternatives to current refrigerants.

Unbiased and wide ranging in its coverage, the TEAP report eschews its normal convention to only discuss refrigerants with ISO/ASHRAE R-number designation, to include a small number of currently unassigned blends where it is anticipated that they are close to commercialisation and receiving R-numbers.

The wide-ranging report looks at efficiencies, potential applications and barriers to market for these alternatives and treads a balanced path between the conflicting claims of both the natural refrigerant lobby and the chemical manufacturers. For instance, the report refers to HFOs as HFCs, a nod, perhaps, to the fact that in reality these new “fourth generation” gases are merely unsaturated HFCs.

Many of the alternatives are blends. “The majority of these blends,” it says, “comprise primarily various unsaturated fluorocarbons such as HFC-1234yf and HFC-1234ze [sic] and HFC-152a and particularly HFC-32 in order to achieve higher vapour pressures.

“Many proposed blends also include R-744 (CO2), HFC-161 and hydrocarbons in small proportions. The selection of the composition is typically a compromise between GWP, flammability and cycle performance measures. The huge number of announced blends and those listed within patent literature infers the considerable research and development activities underway.”

In total TEAP identified in excess of 50 different unassigned blends currently being cited by different refrigerant producers.

It should be noted that refrigerants described as A2L are described as low toxicity, lower flammability. Standards such as ISO-5149 and IEC-60335-2-40 are being updated to accommodate more relaxed requirements for this new class. In practical terms this means that systems located indoors with large charge sizes are often restricted. Similarly, due to uncertainties over future adoption means that there are currently gaps in availability of certain types of components including compressors.

The report also emphasises the need for engineers to be properly trained and competent in handling many of these alternatives due to their flammability, toxicity or high pressure if they are to be treated safely. Some building safety codes may also ban use flammable refrigerants in certain types of buildings. Temperature glide issues in blends may also influence the design of equipment.

Ammonia (R-717)

Ammonia (R-717)

Widely used for more than 100 years, ammonia’s safety classification of B2 (higher toxicity, lower flammability) restricts its use (in direct systems) in occupied spaces. Certain countries also have specific national regulations controlling its use.

It has a zero ODP and zero GWP and offers excellent efficiency. The vapour pressure and refrigerating capacity is similar to R22. However, its high discharge temperature means that for lower temperature applications two stage compression is normally needed.

Ammonia is described as low cost, typically less than $1/kg but generally demands the use of steel piping and components, so smaller capacity systems can cost much more than R22 or HFC systems. As the capacity approaches and exceeds around 400-600kW, ammonia systems can become cost-competitive, says the TEAP report.

There is a lack of suitable components for small capacity systems due to incompatibility with copper and its alloys, although TEAP notes that some companies are working on this.

The TEAP report also acknowledges a lack of well-trained and competent technicians to handle this toxic refrigerant.

Carbon dioxide (R744)

Carbon dioxide (R744)

A single component substance with a safety classification of A1 (lower toxicity, non-flammable), CO2 has a zero ODP and a GWP of 1.

It was used up until the 1930s when it was replaced by CFCs. Since 1990 its use has been revisited and it is currently used in a variety of different types of systems.

CO2 has thermo-physical properties which lead to reasonably good efficiency for certain levels of refrigerant temperatures. The vapour pressure is several times greater than other refrigerants and the volumetric refrigerating capacity is correspondingly higher below around 25°C.

However, with a low critical temperature, the cycle efficiency declines as the temperature before the expansion device increases and other features are needed to achieve similar efficiences to R22 at high ambient conditions. At ambients of 35°C the efficiency of a basic cycle is only about 50-60% of R22. Compared to a basic cycle, the TEAP report notes that 10-20% energy efficiency improvement can be achieved by applying an ejector instead of an ordinary expansion device although using an expander alone can bring the efficiency to within 10% of R22.

Other features identified by TEAP to help improve efficiency in high ambients include economiser (parallel compression), liquid-suction heat exchange and mechanical subcooling. Also, discharge temperatures are very high and therefore, where the high temperature is not to be utilised, technology options such as additional compression stages and inter-cooling must be adopted in system design.

The cost of CO2 is very low but due to its high pressure certain types of systems require more robust designs for pressure safety which adds cost, while specific tube dimensions are much smaller compared to current technology which gives the advantage of compact tubing and insulation material.

Since CO2 can result in a relatively greater drop in capacity at higher ambient conditions compressors may have to be designed with higher upper speeds to compensate for the reduced capacity at off-design conditions). However, as the capacity approaches a certain value (depending upon the type of application, between 50-500 kW), they can become cost-competitive. Similarly the features that are needed to improve efficiency under higher ambient temperature also result in increased cost.

Due to the flammability/toxicity of many of these refrigerants, TEAP emphasises that engineers will also require dedicated training and tooling to use them.

Hydrocarbons

Hydrocarbons (HCs) include three main pure refrigerants, R290 (propane), R1270 (propene) and R600a (isobutane) and a number of blends, R433A, R433B, R433C, R436A, R436B, R441A and R443A, some of which also comprise R170 (ethane). All have a safety classification of A3 (lower toxicity, higher flammability). They have zero ODP and GWP (direct GWP plus indirect GWP) ranges from 1.8 to 5.5.

The pure substances have been used commercially for decades, whilst mixtures such as R436A and R436B have been used since the phase-out of CFC12. Most of the other mixtures are not known to be used commercially, says TEAP. Despite their excellent thermophysical and transport properties, usage is limited due to maximum allowable charge sizes in occupied spaces. Some building safety codes ban use of flammable refrigerants in certain types of buildings.

Generally, the efficiency is shown to be good under most conditions. In principle, they have thermo-physical properties which lead to very good efficiency and low discharge temperatures. Performance comparisons for high ambient conditions are sparse, although two recent studies showed performance to be comparable to R22.

There are currently gaps in availability of certain types of components including compressors. In addition, technicians must be well-trained and competent in handling HCs if the flammability is to be dealt with safely.

R1234yf

R1234yf

Described by TEAP as an HFC, 1234yf is a single component refrigerant with a GWP of about 4. It can replace R134a in same systems since the pressure/temperature characteristics are almost identical. It is classed under FDIS ISO 817 and ASHRAE standard 34-2010 as an A2L refrigerant (low toxicity, lower flammability).

This chemical is currently produced at one medium scale production plant. Further commercial scale production is anticipated when there is a sufficient market demand.

In general this refrigerant is said to produce efficiency levels comparable to R134a although the theoretical COP is a few percent below, says TEAP.

As a new molecule that requires a complex production process, this refrigerant has significantly higher cost than R134a.

The main barriers are related to the safe use of lower flammability refrigerants. Standards such as ISO5149 and IEC-60335-2-40 are being updated to accommodate more relaxed requirements for this new class of A2L refrigerants, says TEAP. In practical terms this means that systems located indoors with large charge sizes are often restricted. Similarly, due to uncertainties over future adoption, there are currently gaps in availability of certain types of components including compressors.

In addition, technicians must be well-trained and competent in handling flammable refrigerants if the flammability is to be dealt with safely. Some building safety codes may ban use flammable refrigerants in certain types of buildings.

R1234ze(E)

HFC-1234ze(E) is a single component refrigerant with a GWP of 6. It can replace HFC-134a in new equipment where its lower volumetric capacity can be addressed in the design of the equipment. Like yf, his refrigerant is classified under FDIS ISO 817 as A2L (low toxicity, lower flammability) so will be subject to similar barriers as 1234yf.

This chemical is already produced at a commercial scale. It is anticipated that this refrigerant will be available as and when there is a market demand.

When used in reciprocating or scroll type of compressors, this refrigerant produces efficiency levels comparable to R134a. When used in scroll and reciprocating compressors, the same POE lubricant oil can be used.

As a new molecule, this refrigerant has higher cost than R134a. This is mainly due to its different manufacturing process and economies of scale. It is expected that as production increases, the price premium would be reduced although it is likely to remain above current costs of 134a.

HCFC-1233zd(E)

HCFC-1233zd(E) is a single component refrigerant with a GWP of 6, which reduces substantially the direct environmental impact. This refrigerant has been submitted for designation and classification to ASHRAE 34, and is likely to be A1 (low toxicity, non-flammable) under that standard as well as ISO 817.

This chemical is already produced at a commercial scale for solvents and blowing agent applications. It is anticipated that this refrigerant will be available as and when there is a market demand.

When used with centrifugal compressors, this refrigerant produces efficiency levels slightly better than HCFC123, allowing the design of systems with very high energy efficiency.

As a new molecule, this refrigerant has higher cost than R123. Still this cost would be moderate and will have a reasonable payback period due to its high energy efficiency which lowers the expenses for end users.

Being non-flammable and having a moderate cost, TEAP says this refrigerant is on a fast track for adoption. R-number designation application is expected this year. There are concerns regarding the decomposition products in the event of a release into the environment.

L-40

L-40 is a mixture of R32, R152a, R1234yf and R1234ze(E) in the ratio of 40/10/20/30%. With a GWP of 290 it reduces substantially the direct environmental impact. It is intended to replace R404A in medium and low temperature refrigeration equipment without any major modifications as its pressures are similar. The components of the mixture are under FDIS ISO 817 as A2 or A2L (low toxicity, lower flammability). As such it is subject to the same barriers on charge size as 1234yf and ze.

All components are already produced at a commercial scale, although currently the production of R1234yf vis-a-vis the market demands for it in automotive air conditioning may be an initial barrier to be overcome. It is anticipated that this refrigerant will be available during the next 1-2 years, says TEAP.

When used in the current R404A system, L-40 is said to exceed the capacity of R404A with an efficiency improvement of around 10%.

The direct cost of this refrigerant is likely to be higher than R404A. It probably works with existing POE lubricants.

The moderate temperature glide of this refrigerant is seen as a potential issue for certain applications such as reversible heat pumps. There are also concerns regarding the decomposition products of some of the components in the event of a release into the environment.

L-20

L-20

L-20 is a mixture of R32, R152a and R1234ze in the proportions of 41.5/10/48.5%. With a GWP of 295 it reduces substantially the direct environmental impact. It replaces R22 in ac equipment without any major modifications as its pressures are similar. As formulated this mixture will be classified under ASHRAE Std. 34 and FDIS ISO 817 as A2L (low toxicity, lower flammability) like 1234yf, ze and 1233zd(E).

All components are already produced at a commercial scale. It is anticipated that this refrigerant will be available during the next 1-2 years in Asia (China, Japan, Korea), followed by other regions (Middle East, Europe).

When used in the current R22 technologies, L-20 is said to match the capacity of R22 with an efficiency ranging from 95% to 97%. Further improvements can produce better efficiencies, especially for cooling only operation in warm climates. The above mentioned good performance in warm climates is mainly due to its relative high critical point (~93°C) compared with other options such as R410A and R32.

The direct cost of this refrigerant is similar to current HFCs such as R407C. It works well with existing POE lubricants. Due to its good efficiency at high ambient temperatures, power consumption would be lower relative to other options.

The moderate temperature glide of this refrigerant may be an issue for certain applications such as reversible heat pumps.

L-41

L-41 is a mixture of HFCs; HFC-32, HFC-1234ze and a small amount of HC-600 (butane) in the proportions 68/29/3%. It replaces R410A in ac equipment. This mixture would likely be classified by ASHRAE Std 34 and FDIS ISO 817 as A2L (low toxicity, lower flammability). It has been already submitted to ASHRAE for classification. It has a GWP of around 460.

All components are already produced at a commercial scale. It is anticipated that this refrigerant will be available during the next 1-2 years in Asia (China, Japan, Korea), followed by other regions (Middle East, Europe). Some countries or regions may take longer than others due to building codes restrictions and lack of regulatory drivers.

The efficiency of L-41 systems is at the same level of R410A. The capacity is approximately 6% to 10% lower than R410A but this capacity is easily recovered in new systems. Discharge temperatures are slightly higher than R410A, still below the limit of existing compressors technologies. Due to its relative higher critical point compared to other refrigerants, L41 performs well at high ambient temperatures.

The direct cost of this refrigerant is similar to R410A. It works well with existing POE lubricants. Power consumption increases its effectiveness at high ambient temperatures relative to R410A.

DR-5

DR-5 is a mixture of HFCs (HFC-32) and HFC-1234yf in the poportions 72.5/27.5%. It has a GWP of 490. It replaces R-410A in AC equipment. All components of the mixture are classified by FDIS ISO 817 as A2L (low toxicity, lower flammability).

All components are already produced at a commercial scale. It is anticipated that this refrigerant will be available during the next 1-2 years in Asia (China, Japan, Korea), followed by other regions (Middle East, Europe).

The efficiency of L-41 systems is at the same level of R410A. The capacity is approximately 6% to 10% lower than R410A but is easily recovered in new systems. Discharge temperatures are slightly higher than R410A, but still below the limit of existing compressors technologies. Due to its relative higher critical point compared to other refrigerants, DR-5 performs well at high ambient temperatures.

The direct cost of this refrigerant would be slightly high as it contains HFC-1234yf which has an expensive manufacturing cost. It works well with existing POE lubricants. Due to its good efficiency at high ambient temperatures, power consumption would be lower relative to R410A.

N-13

N-13 is a binary mixture of HFC-134a (41%) and HFC-1234ze(E) (59%) and is formulated as non-flammable. It has a GWP of 590 therefore reduces substantially the direct environmental impact. It replaces HFC-134a in new equipment where its lower volumetric capacity can be addressed in the design of the equipment. This refrigerant would be classified by FDIS ISO 817 A1 (low toxicity, non-flammability).

These chemicals are already produced at a commercial scale. It is anticipated that this refrigerant will be available during the next 1-2 years in Asia (China, Japan, Korea), followed by other regions (Middle East, Europe).

When used in reciprocating or scroll compressors, this refrigerant produces efficiency levels comparable to HFC-134a. When used in scroll and reciprocating compressors, the same POE lubricant oil can be used.

Being a blend of new molecules HFC-1234ze(E) and existing ones (HFC-134a), its cost is moderate and not significant different from existing blends available in the market.

Being non-flammable and having a moderate cost, this refrigerant is on a fast track for adoption. R-number designation is expected this year.

XP-10

XP-10 is a binary mixture of HFC-134a (44%) and HFC-1234yf (56%) and is non-flammable. It has a GWP of 630 therefore reduces substantially the direct environmental impact. It replaces R134a in new equipment, producing similar capacity and efficiency. As formulated, this refrigerant would be classified by ISO FDIS 817 A1 (low toxicity, non-flammable).

These chemicals are already produced at a commercial scale. It is anticipated that this refrigerant will be available during the next 1-2 years in Asia (China, Japan, Korea), followed by other regions (Middle East, Europe).

When used in reciprocating or scroll compressors, this refrigerant produces efficiency levels comparable to R134a. When used in scroll and reciprocating compressors, the same POE lubricant oil can be used. Due to its high critical temperature, it will perform very well in warm climates.

Being a blend of a high manufacturing cost molecule (HFC-1234yf) and HFC-134a, its cost is expected to be high.

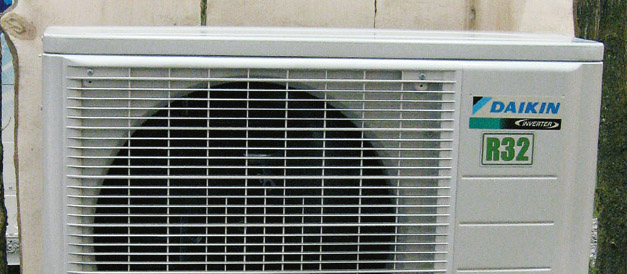

HFC32

HFC32 is a single component refrigerant that was originally used as a component of R410A, which is 50% HFC32 and 50% HFC125, and other blends. HFC125 was used to reduce the flammability of HFC32 and high discharge temperature. With a GWP of 716, it produces a moderate reduction compared to R410A or R22. Pressure and capacity are around 1.5 times higher than R22 and equivalent to R410A. It is classed as A2L (low toxicity, lower flammability) under FDIS ISO 817.

Fairly large production capacity is already available, though commercial availability of cylinders is not yet common.

The efficiency of R32 systems is similar to R410A and the theoretical COP is a few per cent better than R410A at typical air conditioning conditions. The capacity is approximately slightly higher (~ 5%) but it can be easily accommodated with slight adjustment of the compressor displacement in new systems. Its system charge is somewhat lower than for R410A. It has better heat transfer properties and transport properties than R410A due to lower molar mass. Discharge temperatures are significantly higher than R410A. Higher polarity of refrigerant makes necessary the use of new lubricant oils. Some mitigation device or controls are necessary for handling the discharge temperature of the compressor especially at high ambient temperatures.

The direct cost of this refrigerant is lower than R410A as it is not patented substance, simple molecular structure and lower fluorine necessity in molecule. The new lubricant oils and mitigation devices for high discharge temperature may add some cost.

N-40

N-40 is a mixture of saturated HFCs R32 (26%), R125 (26%) and R134a (21%)) with unsaturated HFCs R1234yf (20%) and R1234ze, which as formulated is non-flammable. It has a GWP of 1390 and is therefore similar to pure HFC-134a (7%). It replaces R404A in existing and new refrigeration equipment and would be classified by ASHRAE 34 and FDIS ISO 817 A1 (low toxicity, non-flammable).

The component chemicals are already produced at a commercial scale. It is anticipated that this refrigerant will be available during the next one to two years.

This refrigerant has a capacity marginally higher than R404A and a greater efficiency. The same POE lubricant oil can be used as with R404A.

Being a blend which includes HFC-1234yf and HFC-1234ze, its cost is likely to be higher than conventional HFC mixtures.

No significant barriers are anticipated with this refrigerant for safety. The moderate temperature glide of this refrigerant may be an issue for reversible heat pump applications. Temperature glide issues may influence the design of equipment.

DR-33

DR-33 is a mixture of saturated HFCs R32 (24%), R125 (25%) and R134a (26%) and the unsaturated HFC R1234yf (25%) which as formulated is non-flammable. It has a GWP of 1410 and is therefore similar to pure R134a. It replaces R404A in new refrigeration equipment. This refrigerant would be classified by FDIS ISO 817 A1 (low toxicity, non-flammable).

The component chemicals are already produced at a commercial scale.

Being a blend which includes R1234yf, its cost is likely to be higher than conventional HFC mixtures.

This refrigerant has a capacity marginally higher than R404A and a slightly greater efficiency. The same POE lubricant oil can be used as with R404A.

No significant barriers are anticipated with this refrigerant. The moderate temperature glide of this refrigerant may be an issue for reversible heat pump applications. Temperature glide issues may influence the design of equipment.

Most of the various HFC mixtures without an assigned R-number have a composition that is not yet finalised. Extensive testing by manufacturers is ongoing so minor changes to the composition are still possible.

Subscribe to the Cooling Post newsletter