Sharp intake of efficiency

1st April 2014Regular maintenance is essential to keep refrigerated display equipment running efficiently but such regimes can be expensive. Richard Betts of RAB Specialist Engineers argues that fitting air intake filters could help maintain efficiency and bring down costs.

With energy prices rising and businesses forced to make savings, retail managers from smaller high-street outlets through to major UK supermarket chains are looking at innovative ways to make cuts and reduce energy consumption. While regular maintenance schedules are essential for keeping equipment running efficiently, steps can be taken to reduce these costly regimes that may involve shutting down refrigeration equipment or carrying out expensive repairs during trading hours.

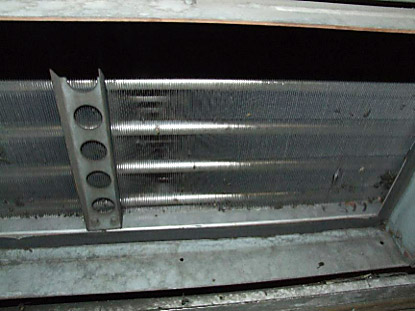

One of the major causes of refrigerator inefficiency or failure is dirty or clogged condenser coils. This results in restricted airflow throughout the system and will require the refrigerators to work harder and consume more electricity in order to maintain the optimum temperatures necessary to avoid food spoilage.

According to Richard Betts, managing director of RAB Specialist Engineers, fitting external air intake filter screens will allow essential cleaning to take place without incurring the costs of specialist refrigeration firms. Clogging of air intake vents caused by outside debris can be avoided and help extend the life of sensitive refrigeration equipment.

Retail energy

It’s not just the smaller sized high-street chains of coffee and sandwich shops that are affected by refrigeration inefficiencies. Research from the Journal of Applied Thermal Engineering in 2010 reported that the UK’s retail food outlets were responsible for approximately 3% of total electrical energy consumption. Refrigeration accounts for a major percentage of in-store electricity demand ranging from 25-30% for larger hypermarkets to over 60% for food-dominant convenience stores. The report concludes that if those stores with above average energy usage reduced their consumption to industry-wide average levels through implementing energy conservation measures, then an additional 10% electrical energy savings could be achieved. This represents around 840GWh of electricity and a reduction of 355,000 tonnes of CO2 emissions if applied to all the stores of the major retail food chains in the UK.

The 2011 Carbon Trust Guide to energy saving opportunities in refrigeration systems that refrigerated display cabinets are estimated to use a minimum of 5,800GWh of energy each year. At current values, and with spiralling energy costs, this is expected to exceed £754m per year and will create a significant drain on the UK’s energy resources at a time when capacity margins are shrinking and warnings of energy blackouts are common..

The 2011 Carbon Trust Guide to energy saving opportunities in refrigeration systems that refrigerated display cabinets are estimated to use a minimum of 5,800GWh of energy each year. At current values, and with spiralling energy costs, this is expected to exceed £754m per year and will create a significant drain on the UK’s energy resources at a time when capacity margins are shrinking and warnings of energy blackouts are common..

Cleaning regime

“One of the quickest and simplest ways to improve energy efficiency and reduce energy consumption is to ensure a regular maintenance schedule for refrigerated display cabinets is carried out,” says Richard Betts. “It’s essential for condensers and evaporators to be kept clean and to ensure fans and defrost systems are working correctly.”

Further guidance from the Carbon Trust suggests that poor maintenance can increase condensing temperature or reduce evaporating temperature by several degrees, resulting in up to a 10% increase in energy use.

The guidance also stresses the importance of avoiding any build up of dirt or debris on the air-intake components. Irregular cleaning schedules can potentially damage a refrigeration unit, resulting in downtime, loss of business and a hefty repair bill. In  short, regularly cleaning condenser coils will maintain compressor efficiency, saving energy and money. The Carbon Trust maintains that cleaning a blocked condenser alone will improve compressor efficiency and save at least 5% in energy.

short, regularly cleaning condenser coils will maintain compressor efficiency, saving energy and money. The Carbon Trust maintains that cleaning a blocked condenser alone will improve compressor efficiency and save at least 5% in energy.

In refrigerated display units the critical components and air intake fins are usually located at foot traffic level and are prone to clogging from airborne debris and dirt.

“To avoid expensive maintenance schedules and prolong the life of sensitive refrigeration equipment, many retail outlets are recognising the benefits of using external air intake filters,” says Richard Betts. This allows regular retail staff to remove and clean them as part of their daily cleaning schedule.

RAB Specialist Engineers offer air intake screens that use magnetic fixings to attach them to the outside of metal air intake louvres, making them easy to position and remove.

Starbucks saves big bucks

Starbucks saves big bucks

In the US, Starbucks Coffee Starbucks installed the air intake filter screens, manufactured by Permatron, as part of its preventative maintenance programme. William Miko, the regional facilities manager for Starbucks’ metro New York had found that clogged refrigeration coils were causing display temperatures to rise throughout his 300 busy stores.

The self-contained, refrigerated, grab-and-go deli/pastry display cases used throughout its stores are designed to display food at eye level, within easy reach.

Located at foot level, the refrigeration components and air intake fans were prone to dirt and dust brought in to the stores by customers. Without frequent cleaning, the clogged coils were causing costly compressor failures that led to loss of sales.

“Following installation of the filter screens, technicians from Starbucks discovered that the display units were running more efficiently and so much colder, that they were able to adjust the refrigeration so that it consumed less energy,” says Richard Betts.

The air intake filter screens have proved so effective that Starbucks is now said to be installing them on its ice-making machines.

UK trials

Several other food and drink outlets closer to home are now also said to be trialling the filters across their stores. Soho Coffee Co, an independent, privately owned Fairtrade business with 24 stores throughout the UK, is currently trialling air intake filter screens in Cheltenham and Bristol.

Commenting on the trials Pete Manuel, property director for Soho Coffee Co said: “We run large display cabinets in busy thoroughfares in shopping centres, all of which take a real hammering from dust ingress. We are trialling these filters in our Cheltenham and Bristol stores to prevent the chiller mechanisms being over loaded with dust, consequently causing high ticket repairs and excessive energy use. Initial indicators show that these air intake filter screens are proving to be very effective in separating nearly all dust from whirling into the chiller components. An additional benefit is that team members are able to remove these filters completely, allowing the dust and dirt be easily cleaned off away from selling areas and customer traffic.”

With over 30 years of professional experience, RAB Specialist Engineers provides consulting and engineering support to the building services sector, including ductwork, pipework, insulation, pump services, heating and ventilation. RAB Specialist Engineers also provides simple and cost effective air intake screens for cooling towers, chillers and hvac systems.