Groups agree on maintenance schedules

15th January 2017

UK: The Catering Equipment Suppliers’ Association (CESA) and the Building Engineering Services Association (BESA) have produced an industry recognised set of maintenance schedules.

This first such independently verified standard provides a recognised set of maintenance schedules designed to help catering managers prolong the operating life of their equipment, reduce running costs, and achieve compliance with relevant legislation.

According to the two organisations, having an independent industry approved standard also gives managers benchmarks against which they can verify the competence of the service providers they employ.

“When we were offered the opportunity to work with BESA on this, we grabbed it with both hands,” said CESA director Keith Warren. “The lack of agreed quality standards created serious confusion for catering managers and meant vital maintenance tasks were simply being neglected.”

The catering equipment standards have been built into BESA’s long-established planned maintenance tool SFG20, which was developed to support facilities management programmes for whole buildings.

This dynamic online software programme allows a facilities manager to produce schedules covering all the main types of equipment found in buildings. It is constantly updated with changes to technical standards and legislation to ensure the building remains compliant. Schedules display how often a task should be carried out and what skill sets are needed to maintain an asset.

“More and more building owners – including increasing numbers in the public sector – are adopting SFG20 as a tool to establish a cost-effective strategy that closely matches user requirements to investment in planned service and maintenance,” said BESA’s head of business development Wayne Terry.

SFG20 already features over 500 maintenance schedules, covering more than 60 equipment types, and gives users the opportunity to customise maintenance schedules, including service times, frequency and criticality ratings.

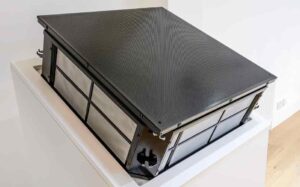

The 105 new schedules cover all aspects of catering equipment maintenance with clear guidelines on levels of work to be carried out, intervals between servicing and operative time required. They encompass everything from coffee machines to cold rooms and storage, from fryers to griddle pans, and ovens, hobs and ranges. They also take account of services like ductwork and grease extract cleaning filter cleaning and replacement, and water treatment.

“Catering managers have always been aware of the need for maintenance, but have often struggled to understand what level of work they should expect from service providers,” said Mr Warren. “These agreed standards provide a vital backstop of knowledge that will allow them to measure the quality of the service they receive and, equally importantly, make the business case for planned, long-term strategies that can extend the lifetime of their equipment and reduce running costs.

“The lack of a common set of standards has meant that some companies simply avoided maintenance completely as they couldn’t measure what they were getting for their money. The SFG20 schedules change all of that and we are now seeing them quoted in FM providers’ tender documents.”

The fact that BIM data can be directly imported into SFG20 schedules is another significant business benefit for catering managers, according to CESA, and it is making this option freely available to its members.

“BIM has a key role to play in creating good operating conditions in buildings,” said Mr Warren. “It is important that there are no cost barriers to its uptake within the catering sector. This initiative complements the CESA BIM resource and further develops CESA’s commitment to taking a lead on the development of digital solutions for the sector.”