Safety alert follows ac “explosions”

26th October 2016AUSTRALIA: A spate of incidents resulting in air conditioning engineers being seriously burned has prompted a safety alert from Australian health and safety authorities.

The safety report was issued by SafeWork NSW, the workplace health and safety regulator for New South Wales, after what was described as a number of serious incidents as a result of the ignition of refrigerant/oil mixtures during servicing.

In the reported cases, workers were using an oxy-acetylene torch to unsweat the copper fittings when replacing a compressor. Although using non-flammable R22, it’s believed that residual pressure in the system caused the refrigerant and oil mixture to be released from the pipe joint, which contacted the oxy-acetylene torch and started a flash fire.

Incidents

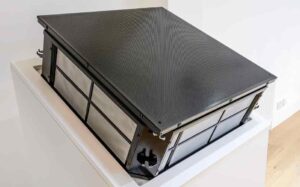

In March 2016, SafeWork NSW confirmed that two workers at a Lake Macquarie, NSW, business sustained burns shortly after one of the workers separated a copper pipe from the discharge outlet of the compressor in a commercial air conditioner using an oxy-acetylene torch.

An earlier incident this year in Melbourne, Victoria, in which an air conditioning unit exploded causing burns to the face, chest and legs of an engineer, is also thought to be connected.

Although failing to recover refrigerant breaches environmental regulations, SafeWork also warns that attempting to break into a system before all residual refrigerant has been removed can cause a sudden release of refrigerant and oil mist, which will be flammable.

Heat from a naked flame will likely result in ignition of any expelled refrigerant and oil mist, and can cause trace amounts of refrigerant to decompose and generate highly toxic fumes.

SafeWork NSW observes that oxy-acetylene torches are commonly used to unsweat copper fittings but warns that this practice can be extremely hazardous and unsafe unless appropriate control measures are taken. It warns that refrigerant will remain in solution with compressor oil unless the refrigerant is completely recovered using a reclaim unit. Warming or agitating the system will also cause the refrigerant to evaporate, resulting in a rise in pressure.

In addition to ensuring the refrigerant is recovered before breaking into the system, it recommends ensuring the work area is well ventilated, and using pipe cutters rather than an oxy-acetylene torch.

UK view

Incidents of this kind and to this extent are rare in the UK but experts warn that such accidents can occur when work is carried out without due care and attention being applied to standard best practice.

“Any brazing or de-brazing should, of course, always be carried out after recovery of any excess gas in a system and after the introduction of an inert gas such as oxygen free nitrogen (OFN) into the pipework,” commented Graeme Fox senior mechanical engineer at UK contractors’ association BESA.

“OFN is used because it inhibits the oxidisation of the internal copper pipes and fittings, but it is important to also remember it expels oxygen from the internal system preventing flash ignition of hot oil – a particular problem when de-brazing welded connections on compressors upon replacement.

“Hazards such as this should always be identified in the RAMS documents produced for work like this and risk reduction/elimination measures should then be taken to ensure accidents like this one are eliminated from normal working procedures.

“As our industry moves increasingly towards the use of flammable refrigerants it becomes ever more essential for technicians to be fully aware of risks like this and to use industry best practice at all times,” he added.

Stephen Benton, a director at UK training consultancy Cool Concerns, points out that the problem is not a new one, but says: “A competent technician will always be aware of the potential for fire during brazing operations not to mention toxic products of decomposition due to the oxy-acetylene flame if refrigerant vapour is present.

“When unbrazing, and after recovery of the refrigerant, the system should be open to atmosphere to avoid any pressure build up inside the system,” he said.

“Gloves and goggles should always be worn together with ensuring an adequate risk assessment has been carried out. A dry powder fire extinguisher should be on hand at all times during hot works and ideally OFN is purged through any pipework being brazed or unbrazed.”

The SafeWork safety alert can be found here.