Predictive technology to cut ac cooling costs

29th June 2016JAPAN: Fujitsu Laboratories, Japan’s largest IT services provider, claims to have developed a technology to predict such metrics as temperature and humidity in data centres.

The technology is said to sequentially build a model that predicts air conditioning effects from collected data, enabling reductions in air conditioner energy use. In this way, it can respond to issues unique to data centres, such as moving information equipment in and out and changing rack arrangements.

Details of this technology was revealed today at the European Control Conference (ECC) in Aalborg, Denmark.

Development background

Data centre energy consumption is increasing along with the growth in the data centre market. The energy consumed by air conditioning equipment is said to account for between 30% and 50% of a data centre’s total energy use, and about 1-2% of all electricity use. Further increases in data centre energy use are expected with the growth of IoT systems.

The Fujitsu technology uses a model-based control (Fig 1), which is used in blast furnaces, automobiles, and robotics to predict future values. The devices installed in a data centre, such as information devices and air conditioning equipment, as well as their layout, can change frequently (Fig 2). This means that the model can diverge from reality over time, reducing prediction accuracy and making it difficult to use in data centres.

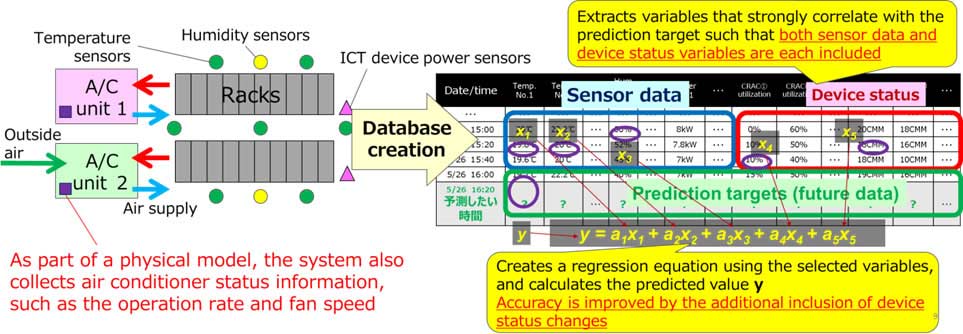

In order to use model-based control in data centres, Fujitsu Laboratories applied Just in Time (JIT) modelling (Fig 3), which can build a model in response to a situation. With existing JIT modelling, useful information is selected from sensor data, including temperature and humidity, through mathematical processing. This data is then used to create a predictive model and calculate predicted values. With the sensor data alone, however, this method does not select enough useful information to immediately reflect the status of dynamic changes in the data centre, making highly accurate predictions difficult.

This new technology creates a database that incorporates the status of air conditioning equipment, including the utilisation rate of machines and fan speed. As well as selecting useful information against prediction targets, it also automatically selects at least one variable from the air conditioning equipment status database. By creating a highly accurate predictive model using the selected variables (Fig 4), this technology succeeds in improving predictive accuracy.

Simulation tests

In a simulation using actual 100-rack scale data, Fujitsu Laboratories says it was possible to predict the temperature of servers’ air supply within an average accuracy of +/-0.17ºC and maximum +/-2.1ºC, even in a frequently changing environment. When applying these results to simulated conditions for a 1,000-rack data centre with servers consuming about 70 million kWh/year, and air conditioning consuming 22 million kWh/year, Fujitsu calculated that savings of 4.5 million kWh in electricity consumption could be achieved – a reduction of about 20%.

Fujitsu Laboratories says it will be conducting field trials of this technology throughout this year, after which it is scheduled to be put into actual operation in 2017.