$2.1m lift for 3D-printed heat exchangers

30th August 2017

USA: A project to develop 3D-printed heat exchangers for refrigerators has received a $2.1m boost from the US government.

In 2015, engineers at the University of Wisconsin-Madison received $2.85m funding from the US Department of Energy Advanced Research Projects Agency-Energy (ARPA-e) programme to develop 3D-printed heat exchangers for power plants. Fuelled by their initial success, the team has now received a further $2.1m to develop 3D-printed heat exchangers for refrigerators.

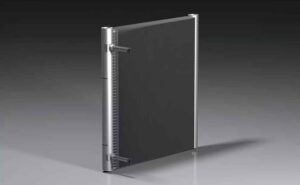

The UW-Madison engineers are using 3D printing to create heat exchangers that have finely detailed geometries with internal projections to increase turbulence and facilitate heat transfer. Such intricate shapes are impossible with traditional manufacturing. Also, at roughly a square foot with a thickness to be determined, the new exchangers are far larger than most case studies to date.

For its work, the team employs a 3D-printing technique known as fused filament fabrication, in which polymer filaments are deposited in layers to “print” 3D products. And to increase the thermal conductivity of the heat exchangers, they use so-called “highly filled” polymers, which they create by adding small copper particles to the polymer filament to impart heat-conducting properties.

The project extension brings aboard the industrial partners Teel Plastics of Baraboo, Wisconsin; Cosine Additive of Houston, Texas; and Greenheck Corporation of Wausau, Wisconsin; to implement the heat exchangers in industrial settings.

The partners are helping set competitive performance and cost targets for the project and provide insights on how to feasibly scale the production of 3D-printed heat exchangers.

Related stories:

3D-printed heat exchanger 20% more efficient – 3 April 2016

USA: A team at the University of Maryland have used the latest 3D printing technology to manufacture a heat exchanger which is said to be 20% more efficient than current technology. Read more…

Are 3D printed heat exchangers viable? – 8 September 2015

USA: A team at the University of Wisconsin-Madison is working with new materials in an effort to produce a viable energy efficient 3D-printed heat exchanger. Read more…