Kaltra updates the microchannel evaporator coil

27th October 2025

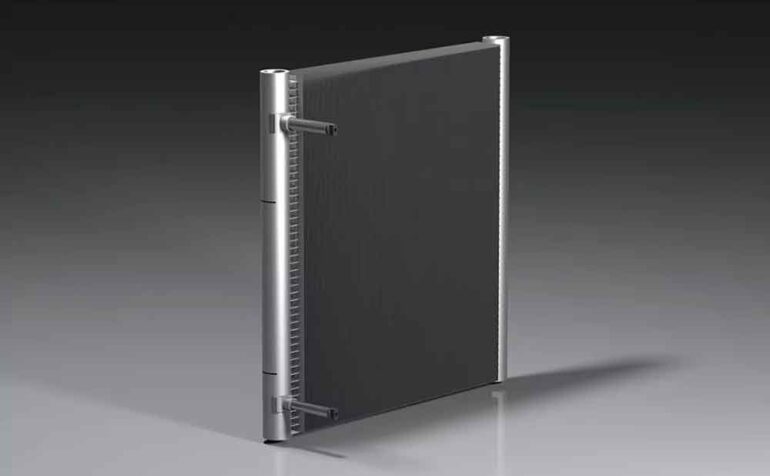

GERMANY: Kaltra has introduced a new series of microchannel evaporator coils that provide stable operation under challenging thermal conditions and enable full reversibility as condenser coils in heat pump applications.

Uniform refrigerant distribution and effective condensate drainage are one of the main engineering challenges in microchannel evaporator design. While Kaltra says that its previous coil generations successfully solved these aspects individually, certain demanding conditions – such as low-load operation, frosting, or use in reversible heat-pump systems – continued to push design limits.

The breakthrough comes with a configuration that places the microchannel tubes horizontally — a layout traditionally avoided in evaporator designs due to poor condensate drainage.

Kaltra says that its engineers overcame this limitation by replacing individual folded fin stripes with vertical louvre-fin plates with leading edges. These edges, which maintain a higher surface temperature than the flat tube, slow the cooling process and direct the formed condensate efficiently downward, ensuring complete drainage and improving frost management and de-icing performance.

With the new vertical louvred-fin plates, condensate drainage and coil behaviour under frosting conditions closely match that of conventional finned-tube coils, as the fin geometry of Kaltra’s new evaporator coils closely resembles that of traditional designs — while retaining all the advantages of microchannel technology.

The new horizontal-tube arrangement additionally allows for multi-pass refrigerant circuitry, delivering higher overall heat-transfer performance and superior efficiency in reversible (condenser) operation.

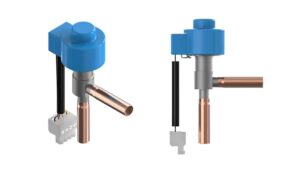

Another key innovation lies in the manifold design. The manifolds feature a special internal geometry with intermediate orifice plates, which promote turbulent mixing of the refrigerant’s gas and liquid fractions. This improves uniformity of refrigerant across all microchannel tubes, ensuring consistent thermal performance and preventing the formation of superheated regions.

The circuit geometry has also been optimised by adjusting the number of tubes in each refrigerant pass, improving overall coil performance for both evaporator and condenser modes.

Kaltra says that the coil’s performance has been confirmed under laboratory and field testing and repeated frosting and defrosting cycles.

Several innovative heat pump manufacturers are said to have already integrated the new Kaltra coils into their systems, reporting measurable improvements in energy efficiency and stability across heating and cooling modes.