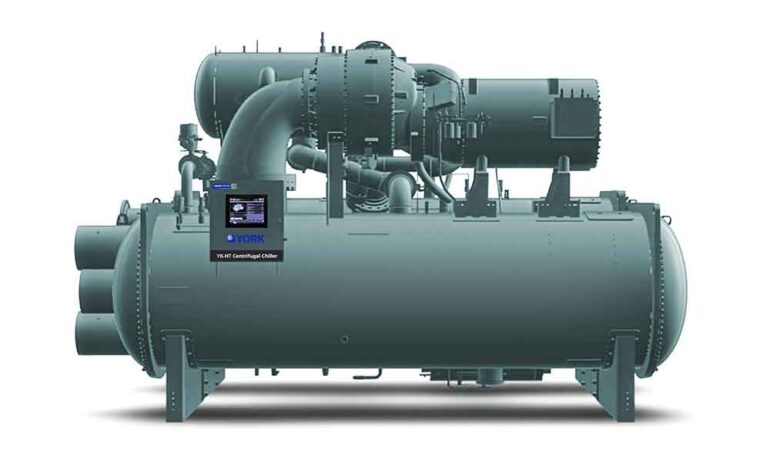

York two-stage economised centrifugal chiller

2nd February 2026

USA: Johnson Controls is previewing the new high-density, compact York YK-HT two-stage economised centrifugal chiller at AHR Expo this week.

Engineered for data centres and large industrial, pharmaceutical and healthcare campuses, the YK‑HT is said to deliver the industry’s widest operating range from a single driveline, operating with condenser leaving fluid temperatures up to 165°F (74ºC) and up to 110°F of lift.

This extended operating range supports closed‑loop heat rejection with dry coolers and enables heat pump and heat recovery applications. By reusing thermal energy that would otherwise be wasted, these systems can offset more than 35MMBtu/hr.

“Water conservation, energy efficiency and decarbonization are priorities for our customers,” said Aaron Lewis, vice president and general manager, Applied Equipment, Johnson Controls.

“The YK‑HT expands what is possible by enabling high‑temperature operation in a compact and efficient platform, helping customers move beyond traditional water‑intensive heat rejection and unlock new opportunities for efficient electrified heating. With its expanded operating range, mission‑critical facilities can scale with confidence while advancing sustainability, performance and long‑term operating efficiency,” commented Aaron Lewis, Johnson Controls applied equipment vice president and general manager.”

These capabilities translate to significant real‑world impact on water and noise as well. For example, a typical 2,000‑ton chiller operating in Las Vegas, where the YK‑HT is previewed, consumes approximately 8 to 9 million gallons (30 to 41 million litres) of cooling‑tower water annually.

When paired with dry coolers, the YK‑HT eliminates that water use entirely. For large data centres, including AI factories facing water conservation constraints and strict noise limits, the YK‑HT’s enhanced lift capability enables up to a 60% reduction in dry coolers and enough fan power reduction to lower onsite noise by as much as 20dBA.

Beyond advanced heat‑rejection performance, the YK‑HT delivers expanded functionality in a single packaged unit. As a unified heating and cooling platform for large buildings, it can produce 44°F chilled water and 140°F hot water at the same time, a normal operating condition for heat pumps, while delivering efficiency levels that exceed ASHRAE requirements.

This unified feature eliminates the need for cascaded systems, extra electrical infrastructure or major mechanical room redesigns. By using a single driveline and reducing rotating components by 50%, the YK-HT simplifies installation and service, while improving uptime.

With Johnson Controls claiming a footprint nearly 30% smaller than most alternatives, the unit is will fit more easily into existing legacy chiller spaces.

The YL-HT uses R1234ze or R515B and includes an integrated lubrication system and dual variable geometry diffuser control flash tank economiser.

The chillers are planned for global distribution and will be manufactured in San Antonio, Texas and Wuxi, China, backed by a robust network of resources, including dedicated support teams and fast service and parts delivery.