LG cuts plastic use on 4-way cassette

18th August 2025

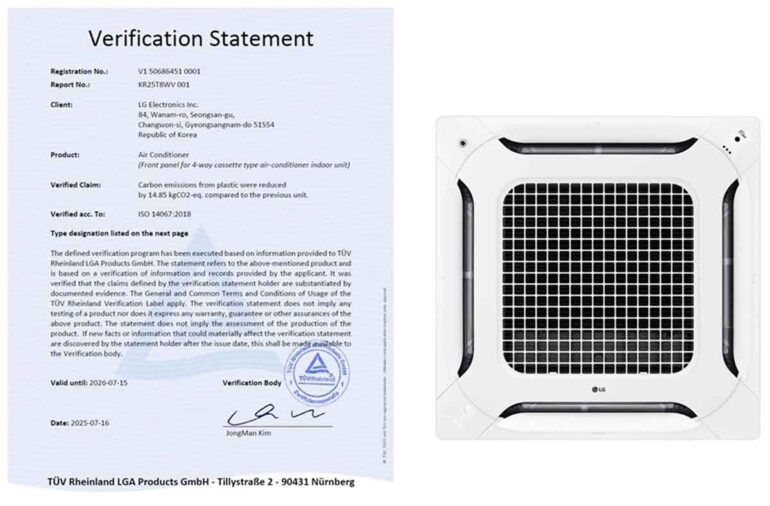

SOUTH KOREA: LG Electronics is reducing plastic consumption and carbon emissions by adopting a new material and manufacturing process for its commercial 4-way system air conditioners.

Testing and certification company TÜV Rheinland has confirmed that LG’s newly instituted production process has lowered carbon emissions from the manufacturing of its 4-way system air conditioners to 14.85kg of CO₂e per unit.

Along with a change in manufacturing method, the primary driver of this reduction is the introduction of a new material used for the air conditioners’ exterior panels.

Moving away from conventional plastic manufacturing techniques, LG employs a foaming injection moulding process whereby nitrogen gas is injected into the mould to create bubbles within the material.

This innovative approach reduces plastic use by approximately 900g per unit. Additionally, LG has replaced the use of ABS with polypropylene, which has a lower carbon footprint.

These improvements are expected to cut plastic consumption by roughly 270 tons annually and CO₂ equivalent carbon emissions by over 4,400 tons each year.

LG began applying its foaming injection moulding method to 4-way system air conditioners in June and plans to gradually expand it to other residential and commercial models.

In pursuit of carbon neutrality, LG says it aims to reduce greenhouse gas emissions by 54.6% by 2030 compared to 2017 levels. To reach this target, the company is integrating high-efficiency equipment into its manufacturing processes and adopting renewable energy sources to produce high-efficiency appliances.