Refrigerant management for developing countries

15th February 2026

FRANCE/USA: The United Nations Environment Programme (UNEP) has signed a new two-year plan with ASHRAE focusing on the lifecycle management of refrigerants.

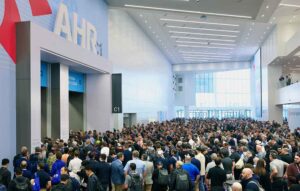

ASHRAE and UNEP have partnered to assist developing countries in transitioning to non-ozone-depleting refrigerants since 2007. The new plan, signed at the recent ASHRAE Winter Conference, calls for joint development of work tools and educational products and expansion of existing resources, looking at refrigerants from production to disposal.

Climate models show that without refrigerant recovery and destruction, net-zero targets are unattainable. Lifecycle refrigerant management (LRM) is seen as a hidden but critical lever for climate action, according to experts.

The new agreement between UNEP and ASHRAE is said to bridge global environmental policy with technical standards and industry practices, ensuring that developing countries can adopt safe, efficient, and climate-friendly refrigerant management systems.

The new work plan is posted on the ASHRAE-UNEP web portal at www.ashrae.org/ashrae-unep-portal.

UNEP’s National Ozone Unit (NOU) officials and others involved in cooling technologies are encouraged to visit the portal to access tools such as self-directed online learning, fact sheets, and checklists to improve refrigerating and air conditioning plant sustainability through improved maintenance.

“The partnership provides specialised products and services that help developing nations manage refrigerants responsibly, meeting obligations under the Montreal Protocol while also advancing energy efficiency,” said Jim Curlin, head of UNEP’s OzonAction Branch.

“ASHRAE contributes to National Ozone Units by providing its technical expertise in codes, norms, and guidelines for refrigerant use, including aspects like flammability, operation, and maintenance. UNEP ensures these standards are deployed in developing countries to align with global environmental goals.”

The new work plan includes the RAC Technicians Field Companion, an AI-powered application based on the mobile application AI chatbot Assessing RAC Plant Sustainability technical guide. The field companion provides technicians with real-time, context-aware guidance and will automate documentation that translate the guide’s guidance into tangible actions.

It also includes a series of briefing documents on topics such as the benefits of lifecycle refrigerant management, how to complete energy audits, safe use and handling of flammable refrigerants, and understanding regulatory requirements related to the use of flammable refrigerants.

A series of educational products are will be evaluated for inclusion of lifecycle refrigerant management guidance. These include online learning of the basics, university course packs, maintenance and refrigerant management checklists and guidance sheets for technicians, and case studies of successful lower GWP refrigerant projects in developing countries.

“Even small leaks reduce system efficiency and increase emissions. LRM emphasizes design, maintenance, and monitoring to minimize leakage,” said ASHRAE president Bill McQuade. “Proper refrigerant charge ensures systems run efficiently, lowering electricity use and indirect emissions. And the economic importance cannot be forgotten. Efficient systems consume less energy, lowering utility bills. Recovered gases can be purified and reused, reducing demand for costly virgin production. Additionally, it leads to job creation because skilled technicians are needed for recovery, recycling, and compliance.”

Jim Wolf, an ASHRAE presidential member who co-chairs the ASHRAE UNEP liaison group, pointed out the need for a safe refrigerant transition in developing countries. “Safety is crucial because some of the new refrigerants are mildly flammable and can pose a risk. Without proper system design and refrigerant handling, leaks can ignite. LRM ensures safe handling, recovery, and disposal under updated standards.”