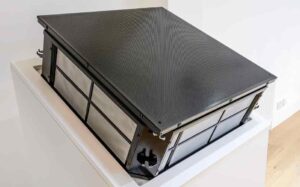

3D-printed heat exchanger 20% more efficient

3rd April 2016 USA: A team at the University of Maryland have used the latest 3D printing technology to manufacture a heat exchanger which is said to be 20% more efficient than current technology.

USA: A team at the University of Maryland have used the latest 3D printing technology to manufacture a heat exchanger which is said to be 20% more efficient than current technology.

Through a partnership with US-based 3D printing developers 3D Systems and the US Department of Energy’s Building Technologies Office, the University of Maryland’s Center for Environmental Energy Engineering (CEEE) used direct metal printing (DMP) to manufacture the miniaturised heat exchanger as a single, continuous piece.

In addition to providing better performance, this next-generation heat exchanger is said to weigh 20% less and can be manufactured more quickly compared to current designs. Being printed in a single, continuous piece, means prototypes are also less likely to leak.

The new 1kW heat exchanger prototype is said to pave the way for new designs and larger models. A 10kW prototype will also be fabricated as part of the current project. Both prototypes will be tested and demonstrated in a 3 ton heat pump. The University of Maryland research team expects the new heat exchangers to be in commercial production within five years.

The use of 3D Systems ProX DMP 320 system, enabled CEEE to prototype its heat exchanger with non-conventional, variable shapes that are not possible to manufacture using traditional forming techniques such as extrusion or stamping.

“DMP allowed us to manufacture highly unusual tube shapes in the form of a hollow droplet to carry the refrigerant,” said Vikrant Aute, director of CEEE’s Modelling and Optimisation Consortium.

“The ProX DMP 320 allows us to deliver open-channel diameters and feature sizes as small as 250 microns in a reliable and repetitive way,” said Jonathan Cornelus, business development manager of 3D Systems’ Quickparts service.

“High pressure and leak-tight exchanger walls can be built as thin as 200 micrometres, which is a true game-changer for heat-exchanger applications,” he added.

Titanium was chosen for the CEEE heat exchanger project, based on its lack of porosity and the ability to provide extremely thin, but very strong, walls. However, the totally new architecture simplifies set-up and is said to be capable of producing all types of part geometries in titanium, stainless steel or nickel super alloy.

The technology would allow manufacturing can be completed in weeks instead of months, enabling CEEE to test designs much earlier and more often during the research programme. The one-part design also helps ensure greater reliability and requires minimal secondary finishing operations.

“With conventional manufacturing technologies, assembly by brazing extremely thin tubes to a manifold is a painstaking operation with very low reliability when it comes to leakages under high-pressure conditions,” said Vikrant Aute. “With DMP technology, no assembly is required since the part is produced in one continuous operation, no matter how complex the parts or how delicate the features.”

Related stories:

https://www.coolingpost.com/world-news/are-3d-printed-heat-exchangers-viable/