Fresh approach for Grundfos motors

14th January 2015 Motors from Danish manufacturer Grundfos are helping one of the world’s largest container companies to maintain the quality of delicate goods as they are shipped around the world.

Motors from Danish manufacturer Grundfos are helping one of the world’s largest container companies to maintain the quality of delicate goods as they are shipped around the world.

It does not take long after purchase for a banana, for instance, to lose its appealing yellow colour and fresh consistency if it is not transported and stored at the optimum temperature.

“Like every fruit, bananas have their own ideal temperature for ripening and storage,” explains Anders Gamborg Holm, general manager for sales and marketing at Maersk Container Industry – the world’s second largest manufacturer of refrigerated containers and refrigeration units for containers.

“We strive to fully appreciate the realities our customers’ customers face and understand their needs in detail, so we can give their goods the best conditions during transportation,” says Anders Gamborg Holm.

The temperature in a Maersk container can be adjusted between -30 and 30°C, to perfectly suit whatever goods are being transported. The latest product variant also provides controlled atmospheres by adjusting the levels of CO2 and oxygen in the air.

“Using this system, we can stop fruit from ripening, so that the maximum transportation time is doubled compared to other refrigerated containers – up to as much as 50 days,” he adds. “This has a major impact, for example, on expanding the market for fruit growers in a number of Central American countries, where production of mangoes, avocados and other fruits far exceeds what can be sold locally during the short season.”

The delicate treatment of the goods inside the containers stands in stark contrast to the extreme conditions they are exposed to on the ships and in the harbours.

“It is not unusual for a crane to drop a container from a height of one metre, or for a wave to wash over an entire container,” explains Kim Axelsen, an engineer in refrigeration, research and development at Maersk Container Industry, whose job it is to test the containers in every conceivable condition.

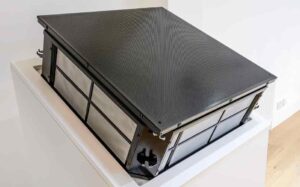

The vast majority of refrigeration systems from Maersk Container Industry use three Grundfos motors. One provides ventilation for the refrigeration unit’s condenser, while the other two provide the required ventilation inside the container by blowing cool air along the floor of the container and up to the goods.

The vast majority of refrigeration systems from Maersk Container Industry use three Grundfos motors. One provides ventilation for the refrigeration unit’s condenser, while the other two provide the required ventilation inside the container by blowing cool air along the floor of the container and up to the goods.

“If the motors fail, the low temperature setting cannot be maintained and there is a great risk of the cargo being lost,” says Kim Axelsen.

As a result, Maersk Container Industry sets stringent requirements for the motors. “From the outset, we told Grundfos that we expected the motors to offer the best possible value for the price, in terms of performance, durability, reliability, and especially energy consumption,” says technical purchaser René Nielsen.

The motors share some of the credit for the fact that the refrigeration unit from Maersk Container Industry uses 20% less energy than competing systems. The low energy consumption is also a major reason why the demand for refrigerated containers is growing by 5% annually on the world market.

Maersk manufactures its refrigerated containers in China and Chile. The Grundfos motors were specially developed for Maersk Container Industry and are produced in such large volumes that they have their own production line at the Grundfos factory in Hungary.