Star demonstrates EcoDesign compliant chiller

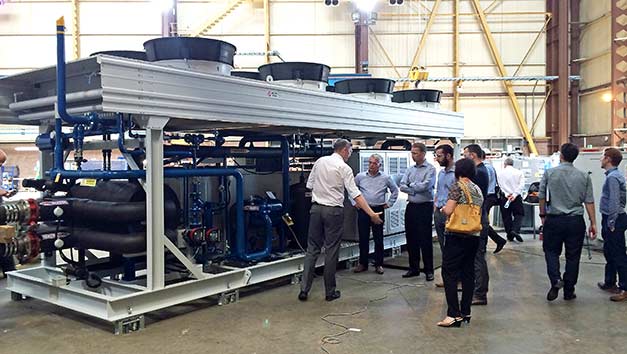

12th June 2016 UK: Guests from across the industry visited Star Refrigeration’s factory in Renfrew on Wednesday for the unveiling of the company’s brand new Azanechiller 2.0.

UK: Guests from across the industry visited Star Refrigeration’s factory in Renfrew on Wednesday for the unveiling of the company’s brand new Azanechiller 2.0.

The visitors witnessed the first-built unit of the EcoDesign compliant chiller in operation, which is said to demonstrate energy efficiency figures 71% higher than the EU Directive Minimum Energy Efficiency Standard (MEPS) requirement.

Guests were treated to a demonstration of the low charge ammonia chiller in action, plus an exclusive run through of current Azanechiller 2.0 installations, including East Kilbride Ice Rink and a number of chilled production facilities.

Dr Lewis Brown, sales engineer at Star Refrigeration, explained: “The benefits East Kilbride ice rink is set to receive from the upgrade to the new Azanechiller 2.0 include cost savings of £13,000 a year in electrical bills in comparison with other ‘best in class’ ammonia chillers, as well as carbon savings of 1,204 tons of CO2 over 20 years. When compared to their previous R22 plant, savings in the region of £30,000 will be expected.”

Star also laid on a CPD-certified EcoDesign Directive crash course to give guests a head start on getting prepared for the EU’s increasing energy efficiency requirements, the first wave of which comes into force next month.

From July 1, it will become mandatory for refrigeration manufacturers of MT and LT process chillers to declare performance and other technical details, in accordance with the EU-wide EcoDesign Directive Minimum Energy Efficiency Standards (MEPS) requirements.

The EcoDesign Directive has emphasised its main goal to be the reduction of energy consumption (and therefore CO2 emissions) and other negative environmental impacts of chillers, particularly at the design stage.

It is expected that through the use of standardised, reliable and application–based energy performance ratios, end users will be able to make better and more informed decisions, which, by taking the total life cycle costs into account as opposed to focusing on capital costs alone, will have the potential to save users millions of pounds on energy bills.

Star’s Azanechiller 2.0 is said to exceed even the tightest MEPS of the directive, with efficiency figures that are up to 146% higher than the European EcoDesign Directive requirement for medium temperature chillers, up to 100% higher for comfort cooling chillers and up to 74% higher for high temperature chiller applications.

The regulations also make provision for each Member State to perform market surveillance checks. For example, any chiller placed on the market post-introduction of the regulations may be selected for testing by a body appointed by the Member State to verify that the chiller achieves the stated performance within an agreed tolerance.

Related stories:

https://www.coolingpost.com/uk-news/star-opens-doors-to-witness-chiller-tests/