Bitzer UK expands remanufacturing

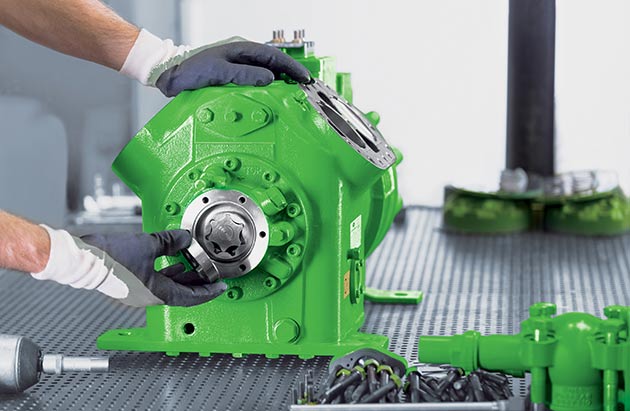

15th March 2018UK: Bitzer’s specialist compressor remanufacturing arm, Green Point UK, has invested in new test facilities which will drastically reduce its turnaround time.

The new facility enables the company to carry out full run tests on remanufactured screw compressors in-house, rather than transporting them to Green Point’s base in France. As a result, turnaround time on remanufactured compressors has been reduced from around three weeks to three days.

It enables Green Point UK to run-test open drive screw compressors at Milton Keynes, with full control and oil separation. The testing station includes a new control panel and associated switch gear.

“Turnaround times can be important on some projects, as, despite our comprehensive stock, it is not possible to stock all models that might be required,” explained Green Point UK general manager Will Pribyl. “The new rapid turnaround time gives customers an edge, enabling them to deliver for their own clients and get systems up and running quickly.”

The investment also includes the addition of further production capacity, to meet growing demand for Green Point’s high quality remanufactured compressors. It will be accompanied with new technical and office support staff over the coming year.

Alongside, stocking of fully remanufactured screw compressors of popular models is being increased, providing a same-day or next-day delivery service on live projects.