Ice rinks on firm ground with ammonia

5th July 2014Ice rink operators, one of the largest users of R22, have been particularly hard hit by the phase out of HCFCs in Europe. With servicing of R22 equipment banned from January 1 next year, an alternative solution is essential if the rinks are to remain open.

For many plant replacement is the best, if costliest, long-term solution with many opting for low-charge ammonia systems.

Live Active Leisure (LAL) which operates 15 leisure venues throughout Perth and Kinross and provides a range of sport and leisure services for the local community called on Johnson Controls to offer a solution for its state-of-the-art curling ice rink at Dewars Centre in Perth.

Since it opened in 1990 the centre has evolved into a first class business and function venue as well as an internationally acclaimed sporting arena.

Live Active Leisure demanded an environmentally friendly and efficient system to replace the existing R22 system. Johnson Controls proposed the creation of an air-cooled ammonia chiller complete with heat recovery and a very low ammonia charge due to the location being close to a pedestrians’ footpath.

The chosen solution included a low charge air-cooled ammonia chiller with three variable-speed-drive screw compressors. Waste heat recovery from a desuperheater and oil coolers for ice pit snow melting were also incorporated.

A SCADA (Supervisory Control and Data Acquisition) was chosen to provide complete remote monitoring of the system. The glycol pumping system also employed variable speed drives

Finally, new flow and return headers were supplied and flow and return individual loops replaced.

Due to controls on the use of ammonia, the skid mounted ammonia chiller could not be placed inside the existing plant room. Johnson Controls set up a new construction outside the building on the loading area and because of the proximity to the near public areas and the intake of goods, the infrastructure had to be made save with consideration given to sound proofing the installation.

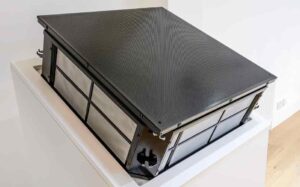

Extensive calculations were completed to ensure the noise was kept to a minimum. EC fans were employed on the air-cooled condenser and the fully-enclosed chiller was made weatherproof and equipped with acoustic removable panels and lockable access doors.

The installation has a low ammonia charge at just 0.3kg/kW of the refrigeration capacity.

The use of a new glycol system, ensured the temperature of the cooling mat was brought down more rapidly which resulted in quicker ice formation than the previous system. Consequently, the hours working on the ice pad formation and running times of the chiller were greatly reduced. And when there is minimum load on the ice rink during off peak hours, the chiller and pumps drop down in capacity to match site conditions.