Green Point warns on compressor burn-out

19th August 2019

UK: Refrigeration contractors and end users are warned of uneven run times on compressors leading to possible burn-outs on multi-compressor packs.

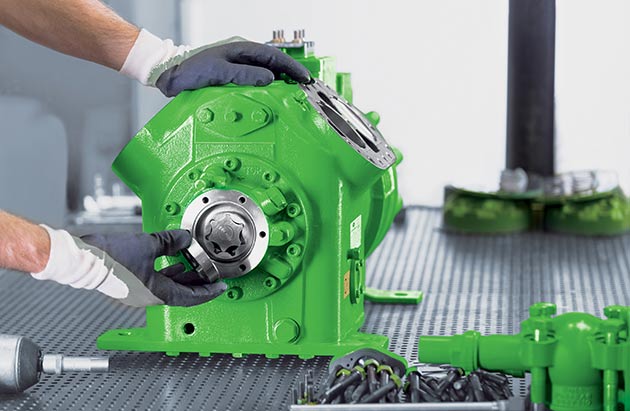

According to Green Point, Bitzer’s compressor remanufacturing and service support arm, the problem occurs on packs with relatively simple control systems whose default run sequence results in extended running hours for certain compressors, while other units remain underused or even idle for extended periods.

It is also said to be an issue where secondary compressors are repeatedly brought into service for short periods to support the primary compressor when additional capacity is required. “Such on-off off cycling over time causes stress to motors, which can result in overheating and, in the extreme cases, complete burn-out,” Green Point says.

“On many multi-compressor packs, a small number of compressors often end up doing much of the work due to the run sequencing control and load profile,” explains Green Point UK general manager Will Pribyl. “This is obviously not ideal and invites trouble. Add to this the problem of compressor cycling on secondary units, and it is an all-too familiar cause of breakdown, with all the consequent costs of downtime and product loss. We see this often in our remanufacturing operations, however it is almost entirely avoidable through planned rotation of compressors.”

He added: “It is a lot less expensive to rotate compressors, removing worn units and remanufacturing and replacing them on a planned basis, rather than waiting for the pack to break down and having to replace the failed unit in an emergency.”

To address the problem, Green Point is introducing a planned compressor rotation service for multi-compressor packs as part of its support for contractors, ensuring plant remains operational and continues to perform efficiently throughout its lifetime.

The approach is said to be aimed particularly at business critical areas such as data centre cooling, the food and drink industry, and high value process applications such as pharmaceuticals and the chemical, oil and gas industries.

“The ideal rotation interval will depend on the operating conditions and running hours for the pack. However, we can advise contractors so they can, in turn, formulate a sensible rotation programme for their end user customer,” said Will Pribyl.

“As the work is planned, we make sure all necessary replacement components are in stock, so turn-around is as fast as possible, usually just a couple of days. However, as the outgoing compressor is removed on site, a like-for-like replacement is immediately installed, so downtime is minimised and system capacity remains unaffected.”

The company says it recently completed a compressor rotation project through distributor RSL Ireland Ltd for an application in Ireland – involving two packs, each with four semi-hermetic screw compressors, serving a blast-freezer in a fish processing facility. One of the lead compressors had failed, prompting an investigation which showed that disproportionate run-time was the cause.

Paul Lynch, RSL Ireland technical manager, said: “The packs had been converted from R404A to R409A a year earlier, but that was not the reason for the failure. The breakdown was due to the pack control disproportionately loading the lead compressor. Green Point was able to supply an immediate exchange compressor to replace the damaged unit, and carry out a follow-up compressor rotation project to avoid similar failures in future.”