Italy’s largest hypermarket goes CO2

26th May 2016ITALY: A question mark has been hanging over the use of CO2 transcritical refrigeration in warm climates but recent advances in Southern Europe suggest it can be an efficient and viable solution.

The Iper Montebello hypermarket in Milan, opened in April, is a pioneer in CO2 transcritical refrigeration system making use of ejector technology to enhance efficiency in temperatures up to 38°C.

The Iper Montebello is part of the new Arese Il Centro shopping centre, erected on the former Alfa Romeo car production site. Building on this proud heritage, Il Centro is the largest shopping centres in Italy and one of the largest in Europe, including 92,000m² of Italian market style floor space with more than 200 shops, cafes and restaurants.

Sustainability is a key pillar of the building designed and constructed to LEED Gold standards to use less water and energy and reduce greenhouse gas emissions.

“Using CO2 to power the refrigeration system is a perfect match to the intentions of LEED. CO2 is a low-GWP refrigerant and an excellent choice when it comes to reducing greenhouse gas emissions. At the same time, CO2 provides high performance and exceptional properties for heat reclaim”, says Gabriele De Bona, key account manager, Danfoss Italy.

Arneg, suppliers of the turnkey refrigeration system, have been convinced by the results of numerous experiments with ejectors in recent years, and decided to go for the new technology in order to enhance the energy efficiency of the hypermarket.

“Electricity for refrigeration makes up 50% of the total energy consumption of the hypermarket, and our customer Iper has an ambition to cut down this consumption year by year as part of their sustainability programme,” explained Arneg’s technical support manager Enrico Zambotto.

The retailer also wanted to switch to natural refrigerants to cut its carbon footprint.

“In order to fulfil these goals, we proposed a transcritical CO2 solution. It is a large installation with several hundred cabinets and cold rooms operating under ambient temperatures up to 38°C.”

In fact, the installation comprises 147 MT cabinets, 29 LT cabinets, 25 MT cold rooms and a LT cold room. Total installed MT refrigeration power is 290kW and LT refrigeration power is 38kW.

While ejector technology is well-known, Danfoss, in close co-operation with Norwegian independent research organisation SINTEF, has devised new ways to use the technology in refrigeration applications to increase the energy efficiency of parallel compression.

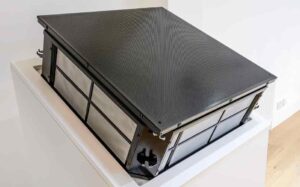

The ejector is still in the prototype stage, but, according to Danfoss, the initial trial set-ups in 15 supermarkets across Europe have shown that a simple ejector can significantly increase efficiency of the system. The energy saving potential with ejectors compared to traditional HFC systems is said to be about 10 %. Ejectors are also said to allow smaller and more compact compressor packs to be installed, reducing the first cost of the installation.

In addition to the ejectors and their controllers, Danfoss also supplied rack and parallel compressor controls. The system also included two compressor racks with seven Dorin compressors and LU-VE condenser.

Danfoss also took part in system design, testing of packs and commissioning.

While it is still too early to provide figures for the actual energy savings of the hypermarket, the experience of Danfoss from similar installations with heat recovery, intelligent control and ejector technology points to energy savings of up to 50% compared to more conventional installations.

“With our Smart Store solutions we can offer energy savings up to 50% depending on the size, location, technology and ambition of the customer,” said Danfoss’ OEM key account manager Gabriele De Bona. “The savings are achieved on all installations from power pack to evaporators and by integrated control of light, HVAC and refrigeration. Our long-term ambition is to lead the development of innovative CO2 solutions and enable net-zero stores or even stores that give more than they take in terms of energy.”