Large Hadron Collider moves to CO2 refrigeration

12th August 2021

SWITZERLAND: Future experiments with the Large Hadron Collider (LHC), the multi-billion pound project to study particle physics, will employ CO2 refrigeration technology.

Following the implementation of the F-gas regulations, CERN, the operators of the LHC, took the decision to transition to move away from HFCs. While it is common for ultra-low temperature applications to use blends of R744 with other “natural” hydrocarbon refrigerants like ethane and ethylene, this was ruled out due to their flammability.

An article by members of the European Organisation for Nuclear Research (CERN) and its collaborators, the Norwegian University of Science and Technology (NTNU) and the University of Cape Town, reveals that the cooling systems of the proposed ATLAS and CMS tracking detector experiments at the LHC will be entirely based on CO2 refrigeration technology.

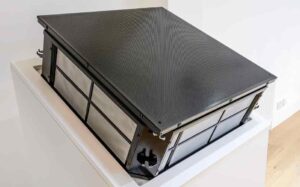

Simplified diagram of the primary system with common equipment, compressor slices and cold box

Stable temperatures

The silicon detectors used to reconstruct the tracks of charged particles in collider experiments need to operate at a stable temperature to maximise the signal to noise ratio. In addition, when subject to radiation, the operational temperature must be lowered below 0°C to minimise the detrimental effects of radiation on their performance.

The upgrade of the LHC for the High Luminosity programme (HL-HLC) starting in 2026, will increase by a factor of 10 the density of the particles created by the collision. This will, in turn, increase of an order of magnitude the radiation level in the detectors.

The large silicon detectors capable of coping with the increased density of tracks will require a new cooling system, capable of evacuating from the detector volume a nominal power up to 300kW for ATLAS and 500kW for CMS, while ensuring a temperature of the refrigerant in the detector heat exchangers down to -43°C.

To achieve this a new CO2 booster refrigeration system has been specially-designed for the project and comprises a two-stage primary with transcritical R744 equipment and a low temperature secondary CO2 pumped loop. The primary refrigeration sub-system installed on the surface provides CO2 at -53°C to the CO2 pumped loops installed 100m underground and rejects the heat exchanged.

CO2 evaporative cooling systems based on mechanically pumped loops are more and more frequently used for particle trackers, because they allow for the use of smaller tubes, while presenting more favourable thermo-physical properties compared to other refrigerants.

The first prototype of the primary system has been installed in a laboratory at CERN. It has been designed with two compressor slices (modules), each with one compressor per compression stage and a common unit. Two different brands of compressors are being used to investigate their performance and reliability. The chiller has been designed to cope with a maximum cooling capacity of 75kW at a suction pressure of 6bar.

Further details of the plans are available here.